The Evolution of CNC Machinery in Woodworking

The journey of CNC woodworking machinery began in the latter half of the 20th century, originating from technologies developed initially for metalworking. Initially seen as an advanced and costly option limited to high-end manufacturing, this machinery has fundamentally altered the woodworking landscape. It offers unparalleled precision and the ability to reproduce complex designs consistently and efficiently. Over the decades, advancements in technology and reductions in cost have made CNC equipment more accessible and increasingly crucial in smaller workshops. This shift has not only democratized high-quality woodworking but also expanded the creative boundaries for wood artisans and manufacturers.

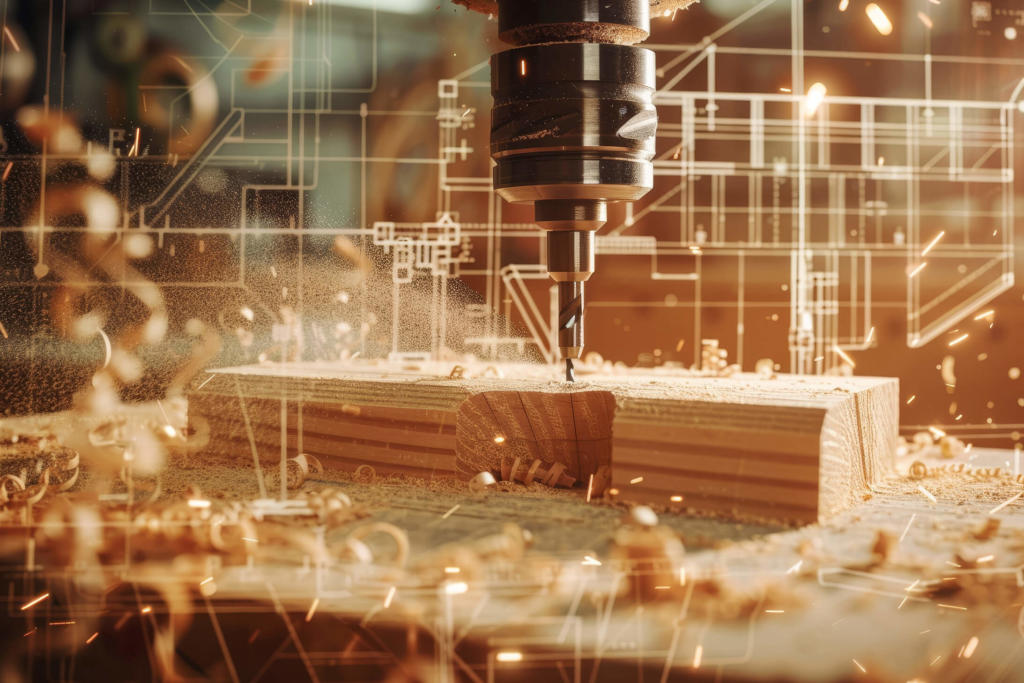

As CNC technology advanced, significant innovations like the integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software became game changers. These tools enable woodworkers to seamlessly translate intricate digital designs into tangible products with minimal error and waste. Improvements in spindle technology and cutting tools have also facilitated the handling of various materials and designs, from delicate inlays to robust furniture pieces. Furthermore, the advent of multi-axis CNC routers has introduced the capability to create complex three-dimensional shapes, opening new avenues for customization and creativity in woodworking. These technological advancements have not only enhanced the efficiency of woodworking practices but also enabled small-scale operators to compete in markets traditionally dominated by larger manufacturers.

Current CNC Woodworking Technologies

The landscape of woodworking has been transformed by the integration of advanced CNC routers and mills, which embody the latest in technology tailored for wood fabrication. These machines bring substantial improvements in operational efficiency, precision, and versatility.

Today’s CNC routers are equipped with dynamic tool-changing systems, high-speed spindles, and sophisticated software integration, enabling them to execute a wide range of tasks from simple cuts to complex, intricate designs with unprecedented accuracy. Understanding the top 5 CNC router features can further help in selecting the right equipment tailored to your needs.

Further enhancing the capabilities of these machines are innovations in software and machine design that allow for greater automation and more precise control. Advanced software solutions help streamline the entire woodworking process from design to finish, improving not only the quality of the outputs but also the speed of production. With these current technologies, CNC woodworking tools can efficiently handle diverse materials and intricate patterns, which once required extensive manual effort and specialized skills, now making high-quality woodworking more accessible and cost-effective for producers at all levels.

Benefits of CNC Woodworking Machinery

Precision and Repeatability

One of the most significant advantages of CNC machinery in woodworking is the exceptional precision and repeatability it offers. CNC machines are designed to execute complex cuts with exacting accuracy, ensuring that every piece is consistent with the next. This level of precision is crucial, especially in large-scale production environments where uniformity and adherence to specific dimensions are essential. Regular maintenance of your CNC router is vital to maintain this precision over time. The ability to replicate intricate designs flawlessly without deviation reduces the margin for error, which is often encountered in manual processes.

Efficiency and Sustainability

Moreover, CNC technology contributes substantially to reducing waste and increasing efficiency in woodworking operations. By optimizing cutting paths and using sophisticated software to plan cuts strategically, CNC machines minimize the amount of material wasted during the manufacturing process. This not only leads to cost savings by making better use of raw materials but also supports sustainable practices by reducing the environmental impact of production. Additionally, the automation provided by CNC machines streamlines workflow, allowing for faster production times and less labor-intensive processes.

Versatility

CNC woodworking machines are also versatile in terms of the variety of materials they can handle. From traditional woods to engineered composites like MDF and melamine, CNC machines can cut through a wide range of materials with precision. This versatility opens up a plethora of opportunities for woodworkers to explore different textures and finishes, expanding their creative horizons and allowing them to cater to a broader market. The ability to work seamlessly across various materials with the same machine enhances operational efficiency, making CNC woodworking machinery a valuable asset in any woodshop.

The Future of CNC Woodworking Machinery

The future of CNC woodworking looks promising, with technological advancements continuing to push the boundaries of what’s possible. One of the most significant trends on the horizon is the integration of artificial intelligence (AI) in CNC technology. AI can dramatically enhance design optimization, allowing for more complex and precise patterns that can be executed with minimal human intervention. This technology will not only speed up the production process but also reduce waste by optimizing the use of materials. Additionally, AI can facilitate predictive maintenance, where the machine predicts and communicates its maintenance needs before breakdowns occur, thereby reducing downtime and improving overall productivity.

Moreover, there is substantial potential for growth in CNC woodworking within various markets, including small businesses and hobbyists. As the technology becomes more accessible and affordable, smaller entities and individual enthusiasts can leverage these advanced tools to produce high-quality work that was previously only possible in larger industrial settings.

This democratization of technology will likely spur innovation in countless niche markets, from custom furniture and home decor to bespoke architectural elements. Furthermore, as online platforms continue to evolve, offering expanded marketplaces for unique, customized products, small-scale woodworkers equipped with CNC capabilities will find new opportunities to reach customers and grow their businesses. This accessibility could transform CNC woodworking from a high-end manufacturing solution to a staple tool in workshops of all sizes.

Elevating Woodworking Artistry

The transformation that CNC machinery has brought to the craft is profound, enabling unprecedented precision, efficiency, and creativity. From large-scale manufacturers to independent artisans, the adoption of CNC technology has redefined traditional woodworking, making it more accessible and versatile. As we look towards a future where technology continues to evolve, embracing CNC woodworking machinery can significantly enhance the capabilities of woodworkers at all levels.

If you’re ready to take your woodworking projects to the next level with CNC technology, reaching out to Mikon can be a pivotal step. As a leading CNC machine supplier, Mikon offers expert guidance and a comprehensive selection of machines tailored to meet diverse woodworking needs. Whether you’re a seasoned professional or just beginning to explore the possibilities of CNC woodworking, the team at Mikon is ready to help you select the perfect machine that aligns with your project goals and budget. Don’t miss the opportunity to enhance your production capabilities and achieve superior results—contact Mikon today to find out how the right CNC machine can transform your woodworking endeavors.